News center

Contact us

Dongguan Ji kerr automation Technology Co., LTD

Telephone:0769-83328418

Fax:0769-83328428

Email:[email protected]

Address:80 Luxi Road, Xixi Village, Liaobu Town, Dongguan City, Guangdong Province

common problem

Home > News center > common problem

News center > common problem

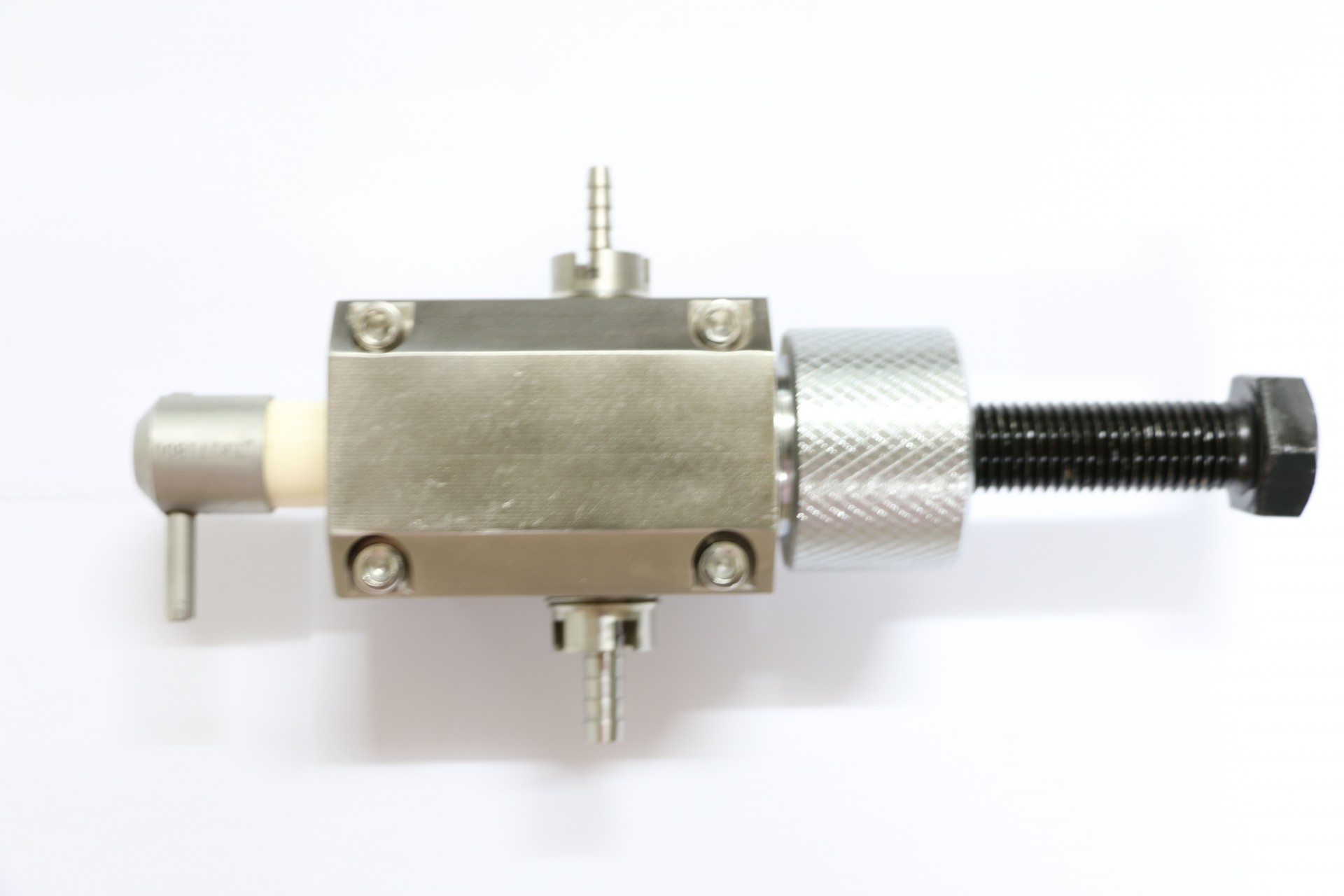

Liquid injection pump stuck pump solution

Date:2018-11-13 browse:2278

First, the ceramic liquid injection pump generally leads to the following reasons:

1. There are micro-particles in the liquid used, causing the pump valve to jam.

2. Electrolyte or other liquid, when the pump valve chamber is not in operation, it is easy to produce crystals,

leading to the pump valve stuck.

3. The left and right inlet and outlet nuts are too tightly locked, resulting in the deformation of the ceramic sleeve.

4. The ceramic plunger rod and the ceramic sleeve are installed incorrectly after the length,

resulting in the ceramic plunger mark topping the front top cover sealing pad when the rotary push and pull operation is done,

resulting in the motor button not moving.

5. If the electric cut-off valve or ball valve at the outlet of the ceramic pump is not opened during operation,

it will also cause the phenomenon of stuck.

Second, the prevention of ceramic liquid injection pump stuck and solutions:

1. Remove the ceramic pump core for cleaning. Pay special attention to use towels, toilet paper or other items to scrub during the cleaning process.

The correct method should only be rinsed with a liquid such as alcohol, water or DMC. If the clamp is very tight,

it is necessary to remove the ceramic plunger rod with a specially equipped booster pump. To prevent this phenomenon,

install a filter on the liquid source to filter the liquid.

2. Electrolyte crystals lead to stuck, some manufacturers recommend boiling water, DMC, alcohol and the like to bubble open,

the other is basically not much use. Take out the ceramic plunger rod with the booster pump specially designed by Jickel.

To prevent such phenomena, the pump valve can be cleaned when it is not in use

Diluent to clean, remove the pump body cleaning.

3. Loosen the left and right inlet and outlet nuts, reinstall them, and control the tightness of the nuts well. Usually,

the strength is tightened by hand and gently belt it with a wrench.

4. The position of the connection between the ceramic plunger rod and the shaft connector is moved inward,

so long as it does not interfere with the rotating push-pull operation.

5. Open the cut-off valve.