Product center

- Precision ceramic piston pump valve series

- Liquid nitrogen point liquid frozen beads series

- Diagnostic reagent drop package series

- Ceramic plunger pipette pump series

- Micro upgrade ceramic metering pump series

- Millilitre ceramic injection pump series

- Intelligent single head metering pump series

- Intelligent multi-head metering pump series

- Ceramic constant current metering pump series

- Large flow rotary valve metering pump series

- High viscosity material variable pump series

- Stainless steel pressure container series

- Ji kerr computer controller series

- Injection pump valve auxiliary accessories series

Contact us

Dongguan Ji kerr automation Technology Co., LTD

Telephone:0769-83328418

Fax:0769-83328428

Email:[email protected]

Address:80 Luxi Road, Xixi Village, Liaobu Town, Dongguan City, Guangdong Province

Precision ceramic piston pump valve series

Home > Product center > Precision ceramic piston pump valve series

Product center > Precision ceramic piston pump valve series

Ceramic filling valve custom series2

Performance Features:

l According to customer requirements, drawings and samples can be made.

l Anti-chemical reaction widely used in transportation of most chemical media.

l The plunger gap is small, it can run continuously without liquid, the filling precision is high, and it can be cleaned and sterilized online.

l Can completely replace imported ceramics.

Telephone:0769-83328418

Message feedbackPrevious:Ceramic filling valve custom series

Detailed introduction

Wide application:suitable for precision filling of corrosive liquids such as oral liquid, biopharmaceuticals, chemical reagents, etc.

Performance Features:

l According to customer requirements, drawings and samples can be made.

l Anti-chemical reaction widely used in transportation of most chemical media.

l The plunger gap is small, it can run continuously without liquid, the filling precision is high, and it can be cleaned and sterilized online.

l Can completely replace imported ceramics.

Technical Parameters

Specification & Model | JKR-GZB JKR-GZB-Plunger Diameter |

Plunger material | Alumina / zirconia / silicon nitride / sapphire (optional) |

Plunger sleeve material | SUS316L Stainless steel SUS316L |

Maximum adaptation temperature | Max1000℃ |

fracture toughness | 8-10 |

Plunger fit clearance | ≤0.002mm |

single range | 0.5-20ml |

Stroke accuracy | ±0.25% |

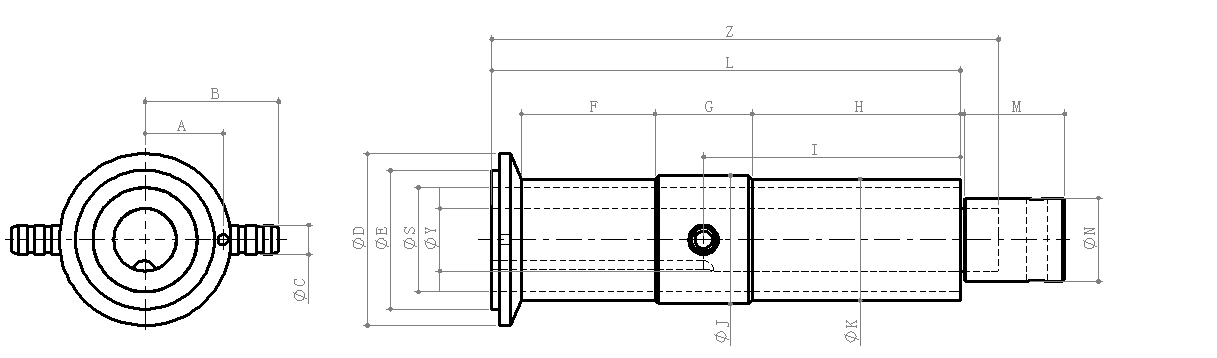

External dimensions:

Suitable for precise filling of corrosive liquid such as oral liquids, bio pharmaceuticals, chemical reagents, etc.