News center

Contact us

Dongguan Ji kerr automation Technology Co., LTD

Telephone:0769-83328418

Fax:0769-83328428

Email:[email protected]

Address:80 Luxi Road, Xixi Village, Liaobu Town, Dongguan City, Guangdong Province

trade news

Home > News center > trade news

News center > trade news

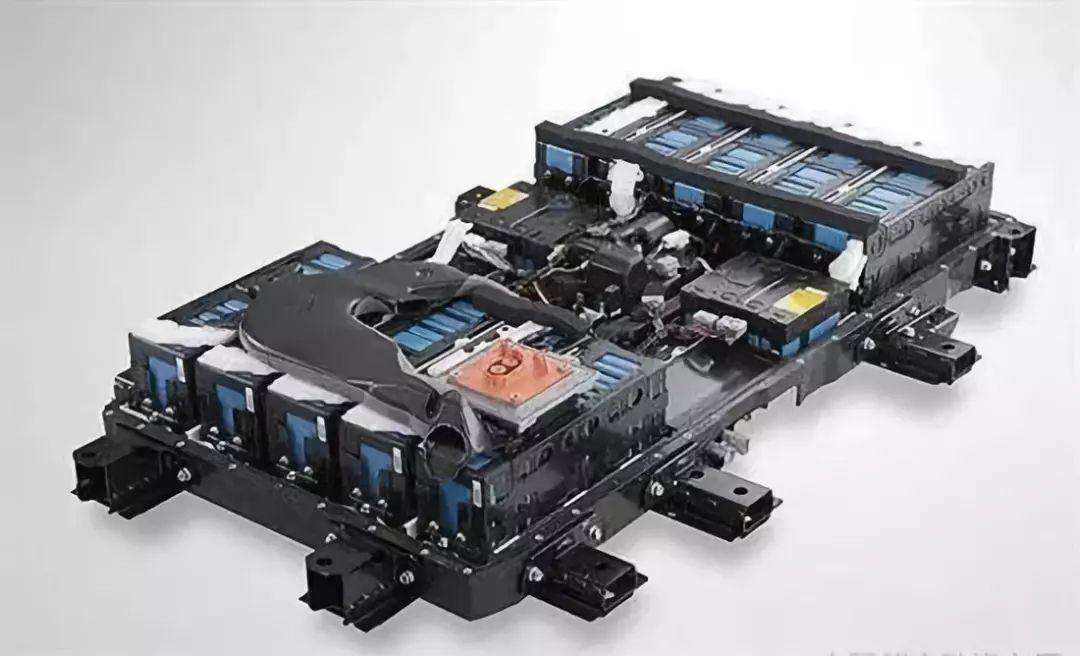

To interpret the recycling and reuse of lithium-ion batteries for new energy vehicles

Date:2022-03-28 browse:264

As more and more countries attach importance to environmental protection, new energy vehicles are being developed and promoted in more and more countries.

At the same time, the industry estimates that in 2015, the cumulative scrap of new energy vehicle batteries is about 20-40,000 tons.

The recycling of lithium-ion batteries for new energy vehicles has become a problem that cannot be ignored.

Power lithium-ion battery life is about 20 years, but the car, only in three to five years will be cancelled, because its capacity attenuation of the initial capacity of less than 80%,

the range of electric vehicles will be significantly reduced, power lithium-ion batteries must be replaced every 3 to 5 years,

so the high price also limits the promotion of electric vehicles important factors. According to China's automotive technology research center experts estimated that in 2015,

China's cumulative scrapped batteries about 20-40,000 tons. By 2020,

the cumulative amount of scrapped batteries for pure electric passenger cars and hybrid passenger cars in China will reach 120,000 to 170,000 tons.

The reporter learned that the technical route of recycling batteries is quite complex, such as in the treatment of waste lithium-ion batteries, first of all,

it must be pretreated, including discharge, disassembly, crushing, sorting; Plastic and iron shells can be recycled after removal;

Then the electrode material was extracted by alkaline leaching and acid leaching, and then extracted by various processes.

The complexity of the process discourages many recyclers.

From the current situation of European and American countries, some manufacturers are vigorously promoting the recycling research and utilization of power lithium-ion batteries,

and reserving large-scale commercial recycling technologies. Belgian company meinecke,

for example, has developed ultra-high temperature technology to treat used lithium-ion batteries. Toyota Motor Corp.

is also working with Toyota Motor Corp. to recycle lithium-ion batteries. An American company is doing the opposite,

treating lithium-ion batteries with liquid nitrogen at ultra-low temperatures to make them chemically inert.

Even Germany, which does not yet have a battery manufacturer, is building a recycling network.

It is understood that at present, China's research on power lithium-ion batteries is mainly focused on improving its safety performance and service life,

and the recycling link is relatively few, and even seriously out of touch. Lithium-ion batteries, power lithium-ion batteries,

contain large amounts of toxic heavy metals such as mercury, cadmium and lead, and their anode and cathode materials,

electrolyte solutions and other substances have a considerable impact on the environment, the number of thousands of tons per year is indeed a problem in the future.

With the overall rise in demand for electric vehicles, lithium-ion batteries will be in short supply by 2017,

so domestic experts call for preliminary research on the recycling of power lithium-ion batteries and the establishment of a special recycling agency.

As more and more countries attach importance to environmental protection, new energy vehicles are being developed and promoted in more and more countries.

At the same time, the industry estimates that in 2015, the cumulative scrap of new energy vehicle batteries is about 20-40,000 tons.

The recycling of lithium-ion batteries for new energy vehicles has become a problem that cannot be ignored.

Statement: The articles published on this website are from the Internet, do not represent the views of this site, if there is infringement, please contact to delete 0769-83328418 (QQ: 287929193)