Product center

- Precision ceramic piston pump valve series

- Liquid nitrogen point liquid frozen beads series

- Diagnostic reagent drop package series

- Ceramic plunger pipette pump series

- Micro upgrade ceramic metering pump series

- Millilitre ceramic injection pump series

- Intelligent single head metering pump series

- Intelligent multi-head metering pump series

- Ceramic constant current metering pump series

- Large flow rotary valve metering pump series

- High viscosity material variable pump series

- Stainless steel pressure container series

- Ji kerr computer controller series

- Injection pump valve auxiliary accessories series

Contact us

Dongguan Ji kerr automation Technology Co., LTD

Telephone:0769-83328418

Fax:0769-83328428

Email:[email protected]

Address:80 Luxi Road, Xixi Village, Liaobu Town, Dongguan City, Guangdong Province

Ceramic constant current metering pump series

Home > Product center > Ceramic constant current metering pump series

Product center > Ceramic constant current metering pump series

No pulsation constant current metering pump series

l All stainless-steel shell, with excellent characteristics such as long service life and corrosion resistance.

l Using a ceramic linkage plunger, the wear resistance is better than metal, ultra-quiet.

l Teflon static seal, good airtightness, no leakage.

l Anti-chemical reaction widely used in most chemical media transportation.

l Energy saving and low power consumption, less heat generation, and can operate continuously for 24 hours.

l The structure design is simple, refined and compact, and the installation method is flexible.

l Controlled by a programmable controller and the parameters are set on a human-machine interface.

l The entire machine is safe, stable, reliable, and easy to operate.

Telephone:0769-83328418

Message feedbackPrevious:no more

Next:no more

Detailed introduction

Application fields: It is suitable for liquid feeding and spraying in the fields of energy, chemical and biological preparations.

Performance characteristics:

l All stainless-steel shell, with excellent characteristics such as long service life and corrosion resistance.

l Using a ceramic linkage plunger, the wear resistance is better than metal, ultra-quiet.

l Teflon static seal, good airtightness, no leakage.

l Anti-chemical reaction widely used in most chemical media transportation.

l Energy saving and low power consumption, less heat generation, and can operate continuously for 24 hours.

l The structure design is simple, refined and compact, and the installation method is flexible.

l Controlled by a programmable controller and the parameters are set on a human-machine interface.

l The entire machine is safe, stable, reliable, and easy to operate.

Technical Parameters

Specification & Model | JKR-WMD-1L/MIN | JKR-WMD-5L/MIN | JKR-WMD-15L/MIN |

Plunger material | Alumina / zirconia / silicon nitride / sapphire (optional) | ||

Driving mode | Stepper motor | ||

Adjustment mode | Digital screen touch screen smart adjustment | ||

Maximum flow | 1L/min | 5L/min | 15ml/min |

Flow accuracy | ±0.3‰ | ±0.4‰ | ±5‰ |

Liquid inlet pipe | Φ2.5×4mm | Φ4×6mm | Φ6×8mm |

Outlet pipe | Φ1.0×1.6mm | Φ2.5×4mm | Φ4×6mm |

Communication interface | RS23 2(485 optional), I/O, CC TRIG, AUX OUT | ||

Power supply | 220V/50HZA or 120V/60HZ (optional) | ||

Work environment | Use temperature and humidity 5-40℃, below 85%RH | ||

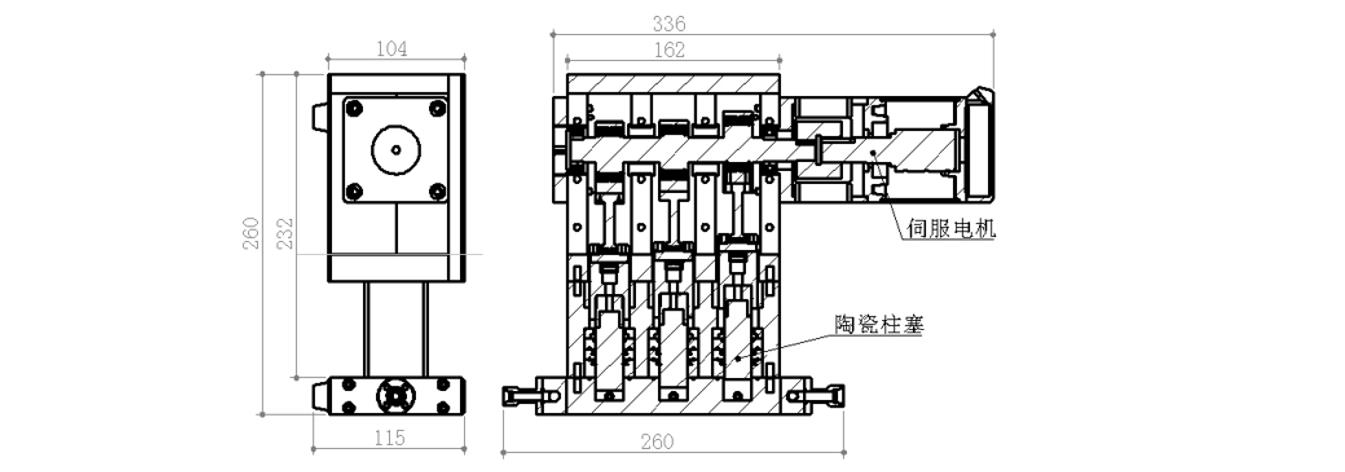

External dimensions

Note: the above models are close to our large shipments of the representative model products, welcome to order customized! For the 2D,3D installation size diagram, please contact our customer, sales or website for download.