News center

Contact us

Dongguan Ji kerr automation Technology Co., LTD

Telephone:0769-83328418

Fax:0769-83328428

Email:[email protected]

Address:80 Luxi Road, Xixi Village, Liaobu Town, Dongguan City, Guangdong Province

Company news

Home > News center > Company news

News center > Company news

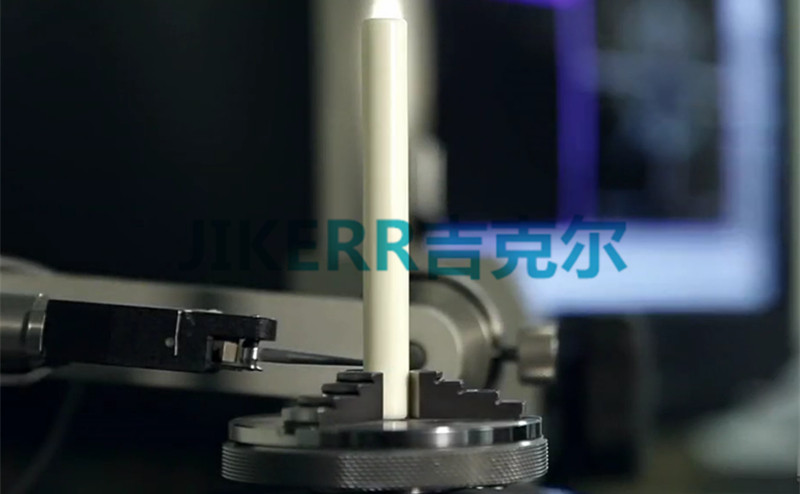

Micro ceramic liquid injection pump developed successful technology

Date:2018-12-21 browse:562

Micro precision filling liquid injection is widely used at present, especially in biomedicine, micro electronics, micro heat pipe, battery injection, chemical reagents and so on.

In order to fully improve the quality and performance of the product to ensure the consistency, stability and repeatability of the filling volume.

Over the years, we Ji kerr R & D engineers have done a lot of research and development in this area,

and obtained a lot of liquid injection pump products that guarantee high experience and stability.

The core of the liquid injection pump is in the spool and control technology.

The valve core is the heart of the liquid injection pump and is an important part of the ceramic liquid injection pump. Its composition has an important influence on the performance,

quality, cost and production of liquid injection pump. The spool serves as the heart of the liquid injection pump. First of all, we must ensure the material selection of the valve core,

and it must have excellent properties such as wear resistance, corrosion resistance, high temperature resistance, health and environmental protection.

At present, we have proved through various studies and tests that can be used to manufacture valve core materials toughness aluminum oxide, zirconia, silicon nitride,

silicon carbide according to the application requirements of different occasions is the first material of liquid injection pump.

Material property | Aluminium oxide(Al2O3) | zirconia | Silicon carbide | Silicon nitride | |

colour | white | white | black | Black ash | |

purity | % | 99.7 | 3Y—TZP | — | — |

use | Corrosion resistance, wear resistance | Wear resistance, corrosion resistance | Wear resistance, heat, corrosion resistance | Wear-resistant, heat-resistant, corrosion-resistant | |

density | Kg/m3×103 | 3.93 | 6 | 3.2 | 3.25 |

Water absorption | % | 0 | 0 | 0 | 0 |

HV hardness | GPa | 18 | 13.2 | 22 | 16 |

Bending strength | MPa | 390 | 1200 | 400 | 700 |

Compressive strength | MPa | 2300 | 3500 | — | 3800 |

Modulus of elasticity | GPa | 375 | 200 | 430 | 290 |

Fracture toughness | Mpa/m | 4 | 7 | 4 | 5 |

Coefficient of thermal expansion | ×10-6/℃ | 7 | 10 | 3.7 | 2.6 |

Thermal conductivity | W/(m·K) | 33 | 3 | 60 | 20 |

Maximum operating temperature | ℃ | 1600 | 200 | — | — |

Heat shock resistance | ℃ | 200 | 200 | 400 | 550 |

Dielectric strength | V/m×106 | 18 | 11 | — | — |

Dielectric constant | — | 9.7 | 33 | — | — |

Dielectric loss coefficient | ×10-4 | 10.06 | 520 | — | — |

Nitric acid | Wt Loss mg/cm2/D | 0.15 | 0.1 | 0.02 | 0.05 |

vitriol | Wt Loss mg/cm2/D | 0.04 | 0.5 | 0.009 | 0.2 |

Aluminium hydroxide | Wt Loss mg/cm2/D | — | 1 | 0.01 | 0.3 |

Ceramic spool is made of ceramic piston and ceramic bushing. Production requirements are very strict, and every process needs to be fully inspected.

The final fit of the ceramic piston and ceramic sleeve should be 1-2 microns.

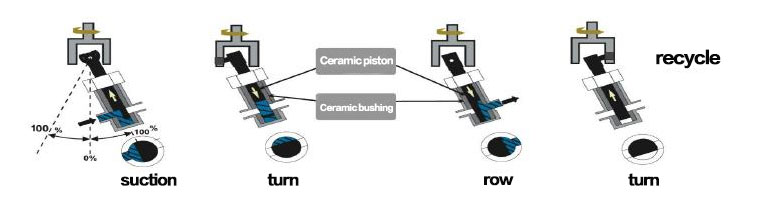

Ceramic injection pump uses ceramic piston and ceramic sleeve to form a relatively closed chamber. Through the motor drive, clockwise reciprocating rotation,

to complete the precise suction and discharge of the fluid to achieve precision metering liquid injection.

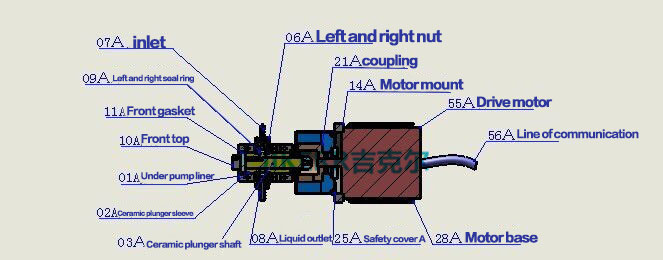

Main composition and function of liquid injection pump:

Spool: ceramic material, ceramic piston and ceramic sleeve precision matching processing to ensure the cavity tightness, no core, no leakage, corrosion resistance, wear resistance.

Body: SUS316 stainless steel

Seal: static seal, PTFE material stable performance to prevent chemical reaction.

Transmission: stepper motor, universal bearing.

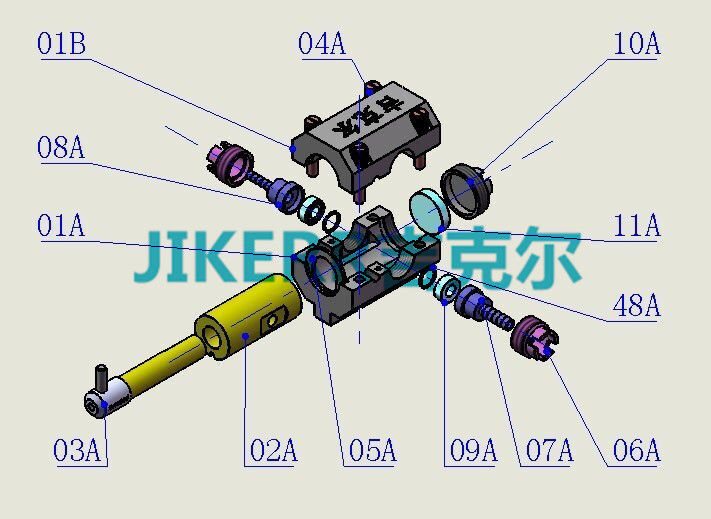

Liquid injection pump and liquid contact parts:

The following ceramic, stainless steel and PTFE in contact with the liquid are environmentally friendly and hygienic,

and are used uniformly with most corrosive liquids to prevent chemical reactions. If it is used for the inlet and outlet of hydrochloric acid and other fluids,

it is necessary to choose a pipe made of PTFE.

Serial number | Material name | material | remark |

1 | Ceramic piston | ceramic | |

2 | Ceramic bushing | ceramic | |

3 | Inlet and outlet | SUS316/ PTFE | |

4 | Left and right seal gaskets | PTFE | |

5 | Front top seal gasket | PTFE |

This article is uploaded and published by Ji kerr official website, the article only represents the author's personal views,

without permission, may not be reproduced.